How Cameras Are Reshaping the Trucking Industry

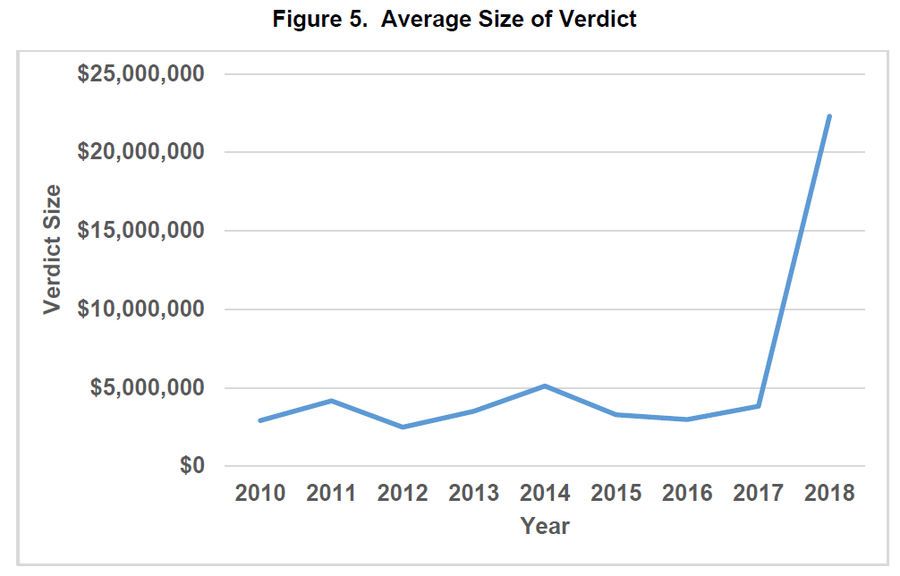

The trucking industry can be a minefield of liabilities. Nuclear verdicts are enough to put an entire carrier out of business with a single at-fault accident, whereas cargo damage claims can quickly add up over time. Even if a carrier doesn’t experience either of these problems, rising insurance costs to protect against them cut deeply into the bottom line.

The good news is that telematics solutions can help reduce these risks by keeping drivers safer on the road and providing greater visibility into assets throughout the business. In particular, dashcams, freightcams and other video technology provide invaluable visual evidence of driver safety issues and cargo status at every step of a journey.

Let’s take a look at two ways that cameras are reshaping the trucking industry and how to effectively add them to your fleet.

The trucking industry can be a minefield of liabilities, but telematics and cameras can effectively reduce these liabilities. Share on XImproving Safety on the Road

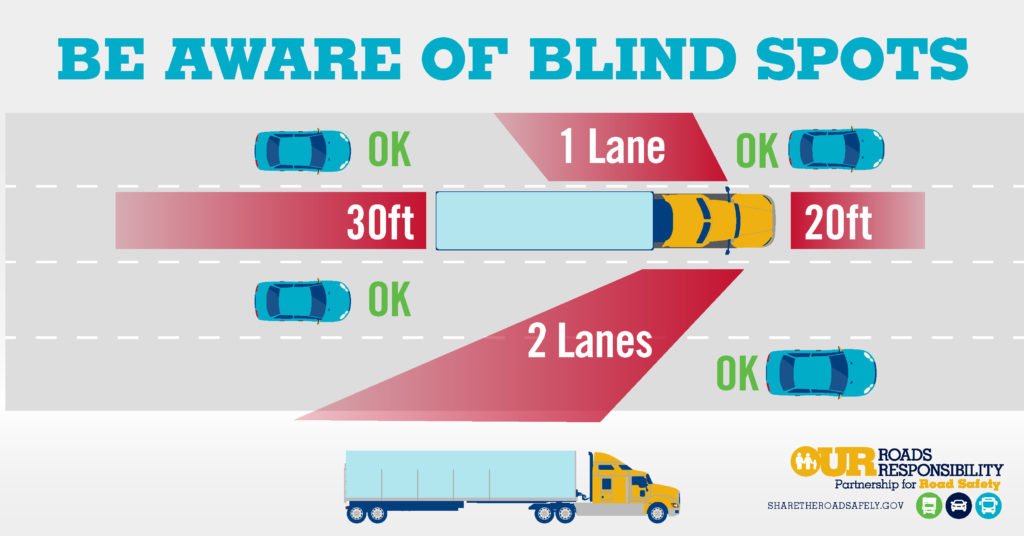

More than 800,000 accidents occur every year due to blind spots, according to the National Highway Transportation & Safety Administration (NHTSA), and more than half of those accidents involve truck blind spots. In many cases, truckers and carriers are considered at-fault for these accidents and may incur significant liability.

Trucks have a number of blind spots, or “no-zones”:

- Front No-Zone: The front no-zone extends about ten car lengths and occurs because truckers sit higher up and the cab obstructs part of the road in front of the truck. If a vehicle cuts in front of a truck too quickly, the driver may not see the vehicle.

- Rear No-Zone: The rear no-zone is a large blind spot directly behind the trailer. If a vehicle is following too closely, a driver may not think anyone is behind them and if they suddenly brake, it could result in them being rear-ended.

- Right No-Zone: The right no-zone is another large blind spot on the right side of the truck. If a vehicle is on the right side of the truck, the driver may not be able to see them when switching lanes and sideswipe them.

- Left No-Zone: The left no-zone is a smaller blind spot that extends roughly one-third the length of the trailer. If a vehicle happens to be in that zone, the driver may not be able to see them and sideswipe them.

- Turning No-Zone: The turning no-zone is a blind spot that occurs when a truck is turning. Vehicles in the angle made by the trailer when it’s swinging to the left or right are in the blind spot and may be hit by the trailer.

Truck Blind Spots – Source: U.S. DoT

Truck drivers are required to adequately monitor their blind spots and carriers must take reasonable precautions to avoid an accident, such as mounting two mirrors on the left and right side of the hood or using back-up sensors to warn drivers when vehicles are in the no-zones. Drivers and carriers may be at-fault if they cannot prove otherwise.

Exterior cameras can help minimize blind spots for drivers by showing drivers the no-zone when they are passing, turning or conducting other maneuvers. In fact, the IIHS found that side-view assist cameras alone could prevent or mitigate up to 39,000 crashes each year, including 2,000 injury crashes and 79 fatal crashes—more than lane departure warnings, electronic stability control, forward collision warning systems.

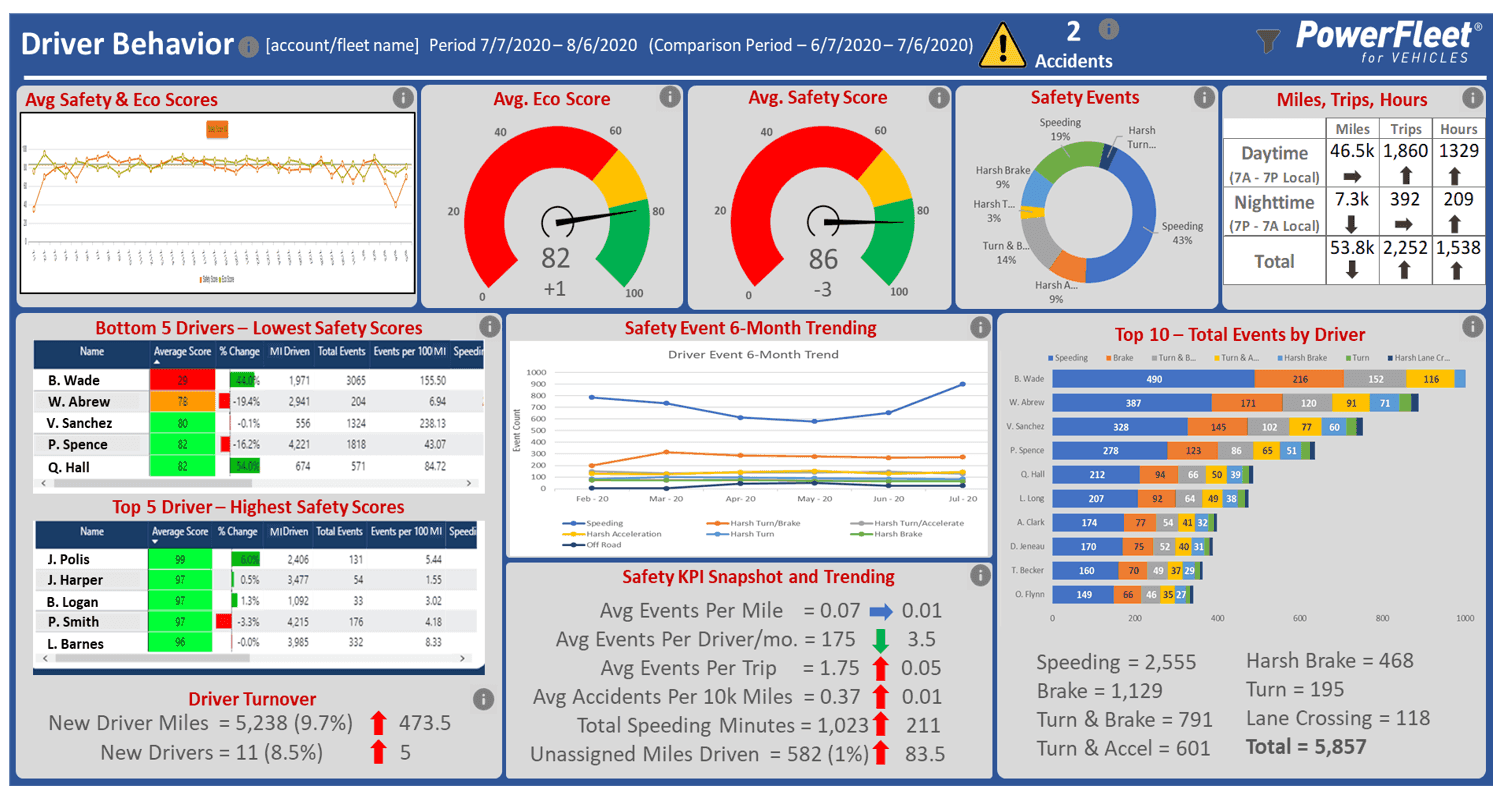

In-cab cameras can also help exonerate drivers that were being reasonably cautious in monitoring blind spots while exterior cameras can show the behavior of other vehicles around the truck. With the average nuclear verdict rising from $2.3 million in 2010 to more than $22.3 million in 2018, exonerating even one fatal crash could mean saving an entire business. The same cameras and telematics can help detect unsafe driving and help companies retrain drivers where necessary and improve safety on the road.

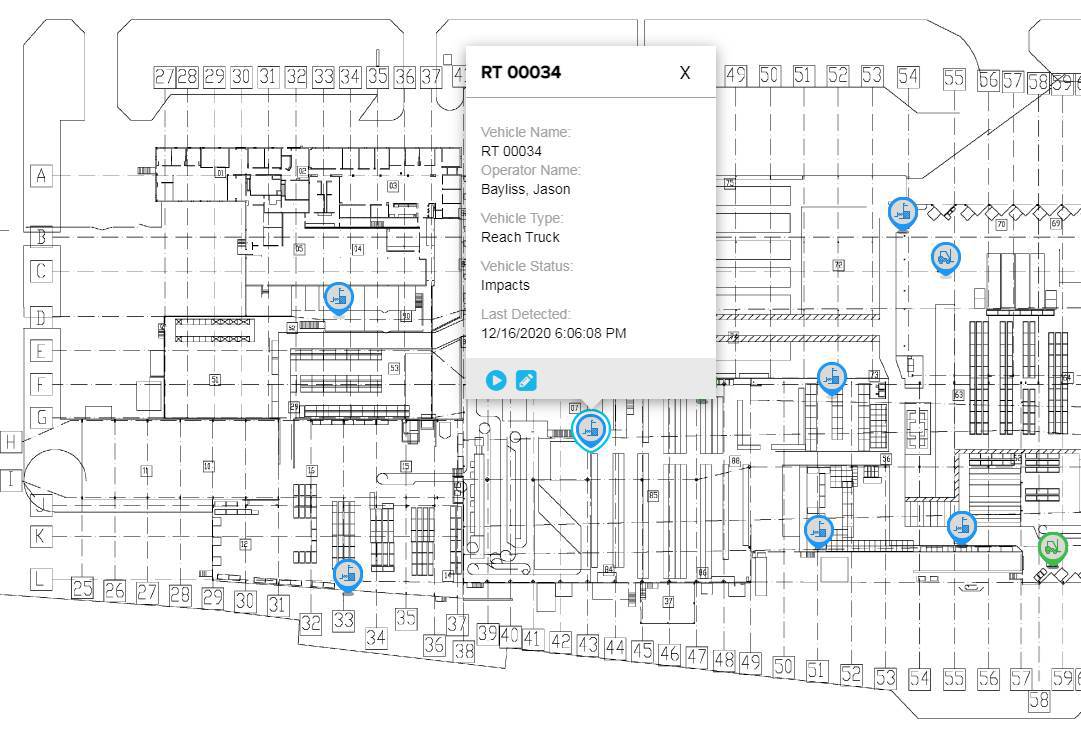

Powerfleet’s solutions support in-cabin and in-vehicle video solutions that operate on a standalone basis or as part of an FMS platform. With the ability to support 360-degree views with side and rear cameras, the products leverage the latest processors and require minimal configuration. They notify drivers of safety events in real-time while a SD card makes it easy to access footage either on the camera or remotely at any time.

Ensuring Cargo is Safe in Transit

Drivers are usually responsible for ensuring that cargo is properly loaded. If they don’t, the carrier could be in for a surprise claim when the truck arrives at the destination. Monitoring cargo is essential to avoid disagreements with customers, or worse, being taken advantage of by unscrupulous shippers and brokers looking for a free ride.

Freight claims typically fall into a few categories:

- Damage: Damage claims occur when the freight is visibly damaged upon arrival.

- Loss: Loss claims occur when the freight was picked up but never delivered.

- Shortage: Shortage claims occur when only part of the expected freight was received, which means pieces could have fallen out or gone missing.

- Concealed: Concealed claims occur when damage is discovered after delivery and reported after the driver leaves.

Under the Carmack Amendment, carriers have strict liability for cargo damage, but claimants must establish that the cargo was picked up in good condition, delivered in damaged condition and resulted in a specific amount of damage. Every freight shipment must also be covered by limited liability but excessive claims can increase insurance cost.

Freight cameras provide visual proof for claims and true freight visibility in transit. For instance, Powerfleet’s LV-710 combines a high-definition camera, image recognition processor, door sensor and cargo area environmental sensor to provide in-depth visibility into trailers. In addition, the LV-740 pallet sensors can detect if pallets are loaded for complete cargo visibility outside of the trailer.

Unlike many competitors, Powerfleet’s central system leverages machine learning to categorize photos and identify trends that would otherwise go unnoticed to the sheer volume of data. The software also prevents users from being bombarded by routine notices that don’t require human intervention, making the system a lot more useful and efficient.

The Bottom Line

Dashcams, freightcams and other video technology have become more widely adopted in the trucking industry. They can help avoid costly liabilities by providing visual evidence of people, vehicles and cargo. In addition to reducing liability from individual events, these technologies could also help reduce insurance costs over time by reducing the number of paid claims.

Powerfleet provides a range of telematics solutions designed to solve logistics problems—including cameras. In addition to its freightcams, the company provides in-cab cameras and ELD-compliant solutions, dry van and reefer tracking solutions, cargo-level visibility tools and chassis and container tracking tools to have full visibility into your fleet.

Contact us today to discuss your requirements and find the right solutions for your fleet!