Detention time is one of the most common complaints among drivers—and free Diet Coke and pretzels does little to help the problem. When looking at the problem more deeply, dwell time inefficiencies cost over $1 billion each year and can even impact safety on the road. Carriers and shippers should work together to solve these problems for themselves and drivers.

Let’s take a look at the impact of rising dwell times and some strategies that both carriers and shippers can implement to reduce it.

Detention time is not only a common complaint among drivers, it costs shippers and carriers more than $1 billion each year.

What’s the Impact of Dwell Time?

Dwell time refers to the total amount of time spent at a facility. According to DAT Solutions, more than 60% of drivers spend more than three hours at the shipper’s dock each time they’re getting loaded and unloaded. A separate survey found that detention times exceeded two hours in 49.5% of deliveries and pickups, with 9.3% exceeding six hours.

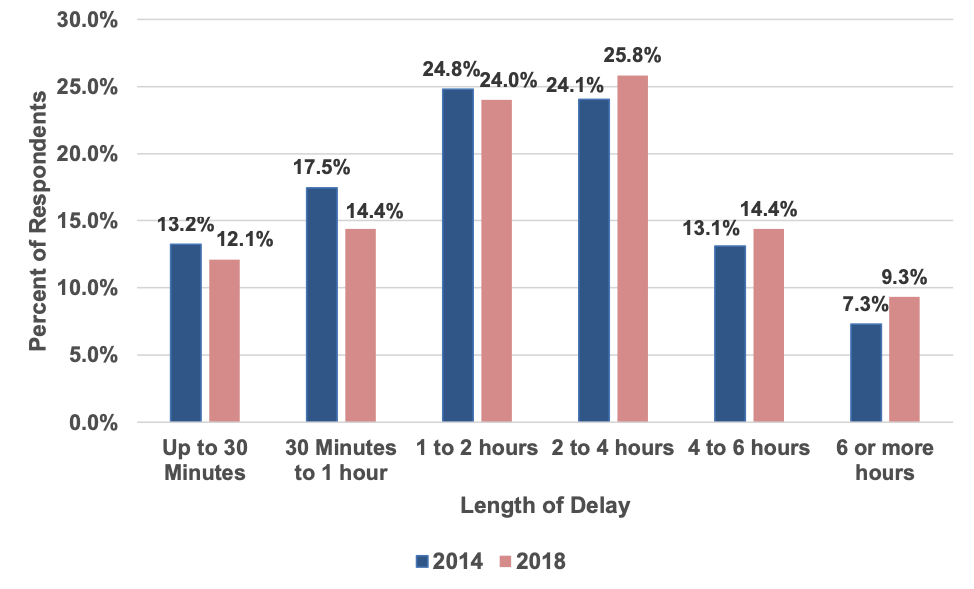

Detention Times Are Getting Worse – Source: ATRI Survey

The ATRI survey found that detention times have worsened between 2014 and 2018—particularly for refrigerated trucks, or reefers. While trucking volumes experienced a lot of gyration during COVID-19, the long-term trend remains toward longer dwell times during periods of normal trucking volume, although that could change post-pandemic.

Detention time—a major component of dwell time—costs drivers and carriers over $1 billion annually and may be associated with increased crash risk, according to the Department of Transportation. Despite frequent complaints from drivers, shippers and receivers aren’t typically aware of or overly concerned by these costs or risk factors.

Dwell time also impacts driver and carrier abilities to meet federal hours of service, or HOS, regulations that limit on-duty hours. In addition to losing on-duty revenue-generating time in detention, electronic logging devices, or ELDs, have made it easier than ever to get caught for HOS violations, which can impact safety ratings or trigger financial penalties.

Finally, there are significant environmental costs associated with dwell time as trucks spend long periods of time idling at picking or delivery facilities. These environmental costs are particularly high for refrigerated trailers that must be kept running at all times.

Tracking & Measuring Dwell Time

Accurate and up-to-date data is a prerequisite to any strategy aimed at reducing dwell time. Without the right statistics in hand, it’s impossible to know the location and severity of problems and come up with the right solutions. The right data can help you pinpoint where problems exist and provide alerts when they go unsolved for too long.

There are several metrics that can help assess dwell time:

- Appointment Rate = Number of Loads / Number of Appointments

- Compliance Rate = Non-Compliant Loads / Total Loads

- Delay Rate = Delayed Arrivals / Total Arrivals

- Average Delay = Total Delay Time per Period / Number of Loads per Period

Powerfleet’s Analytics – Source: Powerfleet

Powerfleet® for Logistics provides in-depth, real-time analytics to comply with federal HOS and FMSA guidelines and track dwell time and asset turns. You can easily gain visibility into exactly where and when a trailer stops, how long it dwells and whether it’s loaded or empty, as well as real-time insights into the dwell times of all trailers in a fleet.

The benefits of these technologies extend well beyond reducing dwell time. Modern tracking systems provide real-time position reports, engine performance information, two-way communication with drivers, environmental status reports and more. These capabilities make it easy to comply with regulations and conduct root cause analyses when problems arise.

Shippers can use the same technology to improve yard visibility by accessing real-time insights into what assets are in the yard by location, their status (loaded or unloaded) and what yards and terminals are operating most efficiently. The information can be used for everything from improving billing accuracy to assessing fleet utilization based on seasonality.

Strategies to Reduce Dwell Time

The primary cause of excessive dwell time is a lack of communication that leads to inaccurate schedules and missed appointments. While both shippers and carriers share responsibility, there are some best practices that can help improve communication and incentivize both parties to keep a tight schedule that minimizes dwell time for drivers.

Appointments

Appointments are critical to ensuring that everything is running on time. By staggering pick up times, shippers can keep their staff focused and reduce dwell times. When the schedule becomes too busy, shippers may want to consider using extended hours, such as weekends, to reduce congestion and make it easier to stick to a regular schedule.

In addition, there should be a simple check-in procedure for arrivals to avoid creating bottlenecks. A paperless check-in process is much faster, less frustrating and more accurate than having drivers fill out paperwork on-site. A lot of the paperwork can also be automated away with technology when using a paperless check-in process.

Detention Fees

A logical way to reconcile lost productivity and incentivize shippers to be on-time is to charge hourly detention fees. While delays can still cause issues downstream, these fees can partially offset productivity losses for both drivers and carriers. The ATRI survey found that about half of carriers charge $50 to $69 per hour and one-third charge more than $70 per hour.

Live Loads

Modern technologies are opening the door to live loading possibilities. By designating “live load” dock doors, shippers can load a trailer immediately after it docks to virtually eliminate dwell time. These live loads may only be possible under a specific set of circumstances, but when they occur, they can make a big dent on averages over time.

Drop Trailers

Drop-and-hook systems remove dwell time from the equation by enabling truck drivers to simply unhitch their trailers and keep moving onward. By keeping loaded trailers available and organized, these systems can virtually eliminate dwell times and keep products moving quickly—a win-win situation for drivers, carriers and shippers.

The Bottom Line

Dwell time—and especially detention time—is a major problem in the trucking industry. Fortunately, there are several strategies that both shippers and carriers can use to mitigate the problem. Most of these solutions rely on technology at the core in order to pinpoint problems, improve communication and keep tighter schedules.

Learn more about Powerfleet® for Logistics and how it can help your business stay on track through greater visibility or contact us today to schedule a free consultation.