4 Must-Have Automations for Field Service Fleets

From plumbers to maintenance/warranty service professionals, many organizations have one foot in the transportation business with their field service fleets. Managing these private fleets can be a headache for companies that are already busy with their core business. Fortunately, new technologies have made it much easier to manage commercial vehicle fleets while opening the door to new opportunities.

Let’s look at four ways to leverage technology to automate mission-critical tasks and open the door to new capabilities.

New technologies have made it easier to manage private fleets while opening the door to new opportunities. Share on X#1. Track Assets with GPS

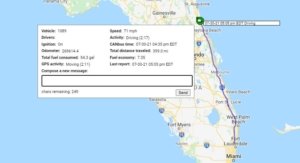

Most drivers already use GPS navigation to find their way to client sites, but relatively few businesses use the same technology to track company vehicles. Rather than calling drivers to get a status update or checking lots for a vehicle, GPS technologies make it easy to see real-time locations on a web or mobile dashboard without any effort.

There are several other benefits to tracking vehicles:

- Dispatchers have greater visibility into vehicle locations when talking with customers or assigning jobs.

- Customers can track the real-time location of delivery vehicles or accurately estimate the arrival times of technicians.

- Business owners can see where vehicles are located across different areas and maximize fleet utilization.

The same technology can also help reduce risk:

- Many insurance companies offer discounts to GPS-enabled fleets since the technology reduces the likelihood of theft or loss.

- Business owners can prevent inappropriate vehicle use by employees, such as running personal errands.

#2. Improve Safety with Telematics

Driver safety is always a top priority. In addition to the human costs of an accident, companies could be on the hook for tens of thousands of dollars—or even millions—in damages along with permanently higher insurance premiums. Driver training and ride-alongs can help improve safety, but it’s a tedious and costly process that ties up employees.

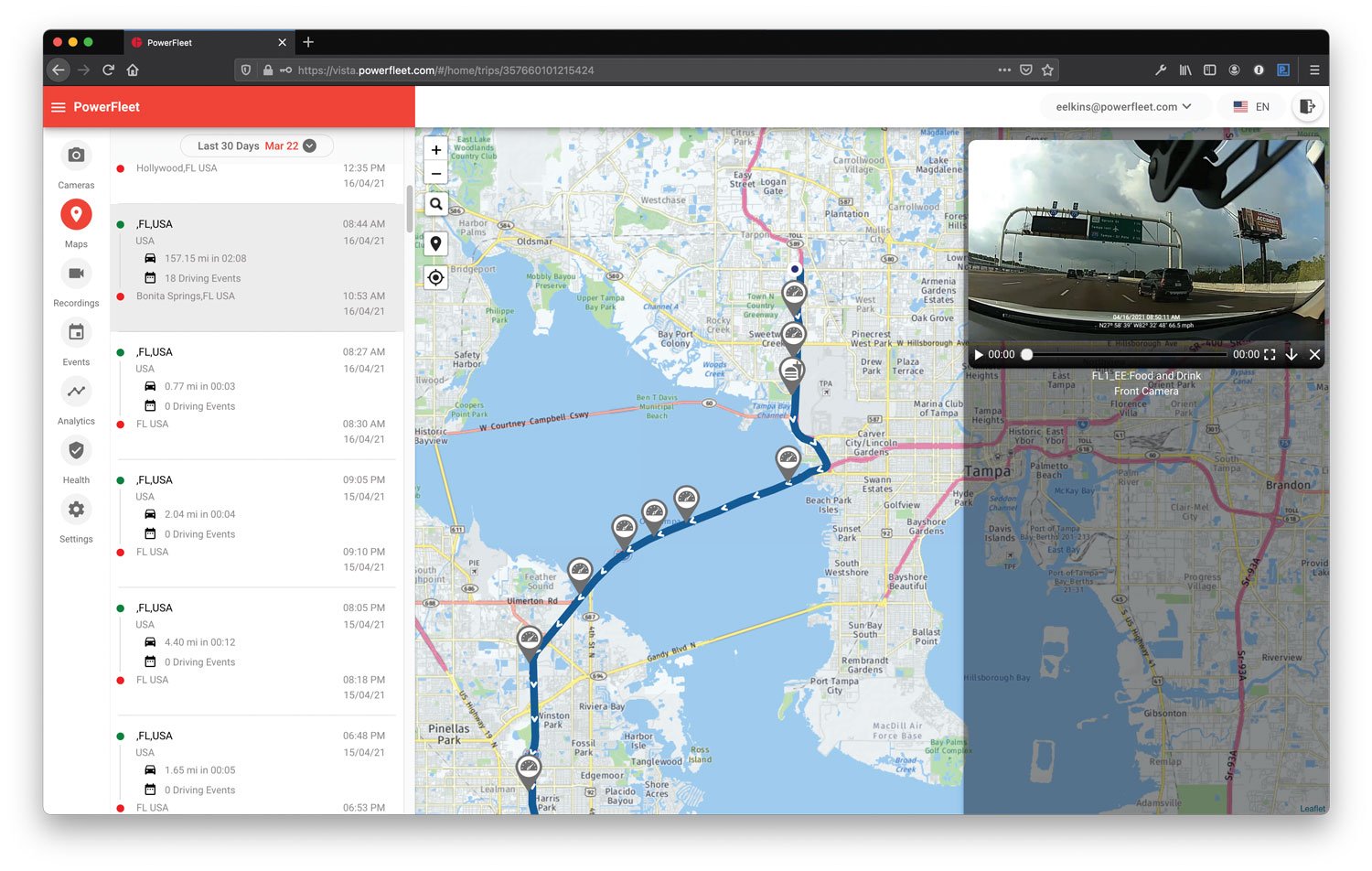

Telematics solutions provide real-time insights into driver behavior that you can use to automate driver assessments, build incentive programs for good driving, and retrain poor drivers to reduce the risk of accidents. For example, you can measure speeding, harsh braking, sudden acceleration, and cornering and tie those behaviors to specific drivers.

Powerfleet’s Vista makes it easy to manage your fleet – Source: Powerfleet

In addition to driver telematics, integrated cargo-hold sensors can monitor temperature and humidity, as well as provide alerts when there’s a sudden shock that might cause movement. These technologies can help eliminate the need for drivers to monitor cargo-hold conditions and help businesses defend against unwarranted damage claims.

Dashcams can augment these telematics to provide another layer of security. Cameras give the drivers 360-degree situational awareness and businesses video evidence to support insurance claims when incidents occur. Integration with telematics solutions also ensures meaningful driver scores and captures footage of dangerous events.

#3. Plan Better with Analytics

The best way to make any decision is with the right data. With vehicle locations, driver behaviors, and other data points, fleet management software can automatically optimize routes to reduce time and maximize fuel efficiency. You can also gain insights into the average deliveries a driver makes or the average time a technician spends at a job site.

In addition to improving the customer experience and reducing stress for employees with optimal routes, the same data points can help optimize asset utilization. For example, you can analyze vehicle usage patterns to right-size your fleet and reduce costs. Or, you can confidently time vehicle purchases for when you know there’s ample utilization potential.

More data is also helpful when building budgets. With granular data covering fuel consumption, vehicle maintenance, and other costs, managers can create more accurate forecasts to help businesses better manage their cash flow. Applying artificial intelligence can further improve these forecasts by searching for deeper patterns in the data.

#4. Preventative Maintenance

Vehicle breakdowns are frustrating for everyone, but they can be exceptionally costly for businesses. When a company vehicle breaks down, businesses lose out on potential revenue while still paying employees. You may even have to pay for towing and emergency rates to ensure that the vehicle is quickly repaired and back on the road.

Telematics goes beyond looking at the odometer for maintenance. Instead, you can gain access to over-the-air diagnostics and implement preventative maintenance that’s determined by wear-and-tear, not miles driven. The result is fewer breakdowns, lower maintenance costs, and improved fleet utilization and profitability over time.

Predictive maintenance technologies can also help determine when it’s time to replace fleet assets. With proper planning, you can typically negotiate better deals than a last-minute vehicle replacement and group purchases to obtain volume discounts. You can even use usage data to determine the optimal vehicle make and model for the job.

Powerfleet’s Platform

Powerfleet’s Field Service Management Platform is an integrated solution specifically engineered to solve the complex challenges of next-gen fleet operators, regardless of size.

The platform makes it easy to:

- Establish data-driven and goal-oriented safety and productivity measures across your fleet to improve constantly.

- Track real-time locations for fleet assets and create customizable geofences to simplify management.

- Plan optimized routes for enhanced ETAs, less stressful driving experiences, and a better customer experience.

- Measure everything from fuel usage to the temperature and humidity of the cargo hold in real-time.

- Protect assets with real-time monitoring of locations and dashcams to provide unparalleled visibility.

Powerfleet provides simple ordering, training, and onboarding to minimize downtime and realize an immediate return on investment. If any issues arise, we provide 24/7 customer support to help keep your fleet running smoothly.

Contact us today to learn more!

The Bottom Line

Managing a fleet is no small task, but technology simplifies the job. With Powerfleet’s Field Service Management solutions, you can access unparalleled visibility and streamline your workflows. In addition, the relatively low cost and widespread benefits of these solutions can help create a rapid payback period and attractive long-term ROI.

Contact us today to schedule a free consultation!