How to Maintain Safety with Seasonal Workers in Materials Handling

Supply chains are under tremendous pressure thanks to labor and parts shortages. The holidays will compound these issues as companies look to scale up their seasonal workforces. While finding labor is a huge challenge, companies shouldn’t neglect workplace safety. Forklift accidents alone cause more than 7,000 non-fatal injuries and 600 deaths each year.

Let’s take a look at how to ensure seasonal and temporary workers adhere to the highest safety standards.

Many businesses struggle to find workers to meet demand, but they shouldn't neglect workplace safety. Share on XForklift Safety Requirements

Seasonal and full-time employees must abide by the same safety standards. OSHA provides a minimum set of safety standards—and violations range from a warning to as much as $136,532 per incident. The penalties are exceptionally stiff for companies that don’t implement the policies and procedures to ensure workplace safety.

But, of course, many employers go well beyond these minimums due to the high cost of workers’ compensation and lawsuits. The NCCI estimates that lost-time workers’ compensation claims caused by motor vehicle crashes averaged about $78,446 per claim in 2017 and 2018, while even minor cuts or scrapes cost upwards of $23,000 per claim.

OSHA’s safety requirements for employers include:

- Employers shall ensure that each powered industrial truck operator can operate a forklift safely by complying with training program requirements and safety management and safety programs specific to forklifts. (29 CFR 1910.178(l)(1)(i))

- Employers should not allow anyone to walk beneath the elevated portion of a forklift. (29 CFR 1910.178(m)(2))

- All forklifts must be examined at least daily before being placed in service, and forklifts used around the clock must be examined after each shift. (29 CFR 1910.178(q)(7))

- Any powered industrial truck that’s not in safe operating condition shall be removed from service, and all repairs should be made by authorized personnel. (29 CFR 1910.178(q)(1))

- Defects must be immediately reported and corrected. (29 CFR 1910.178(q)(7))

When hiring seasonal workers, employers should take the time to train each new employee. Never rely on a worker’s past experience operating forklifts since their training may have been inadequate, or worse, fabricated. When training seasonal workers, document their training and have them sign off on a form indicating that they’re up to speed.

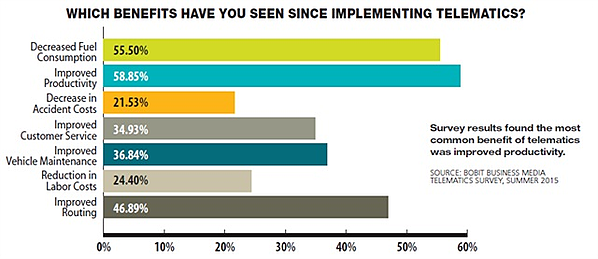

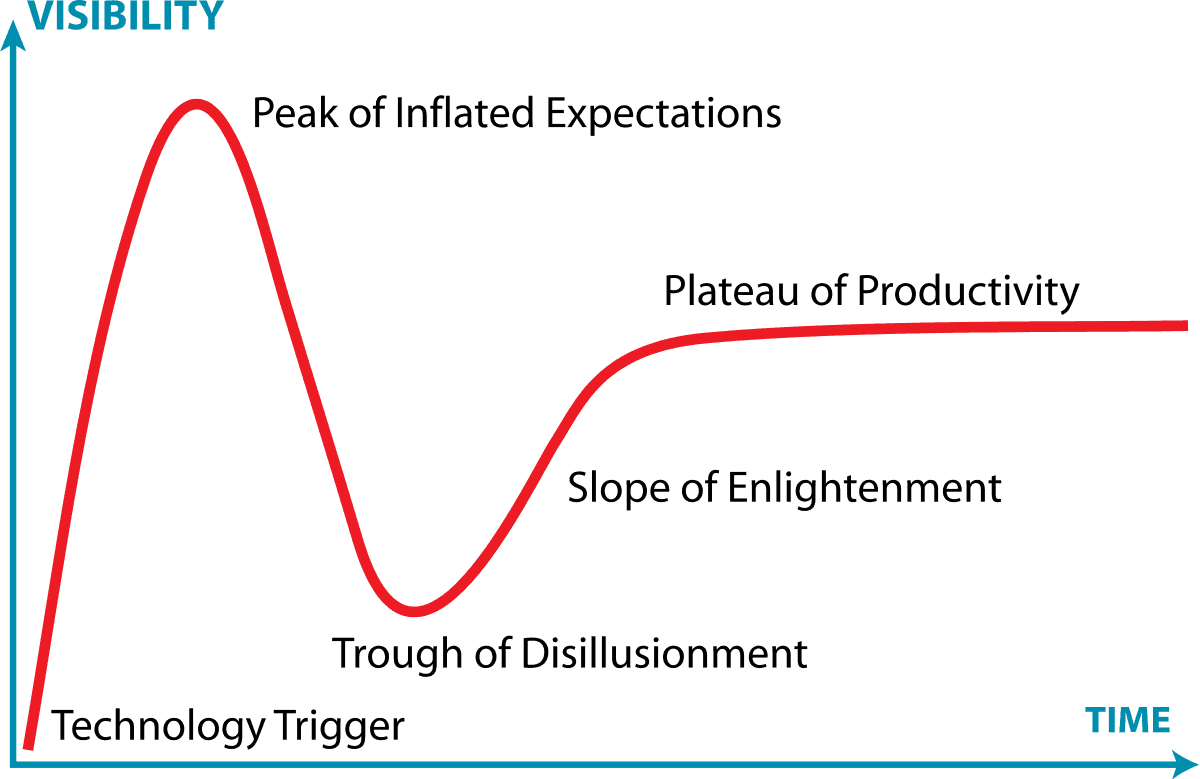

How Telematics Can Help

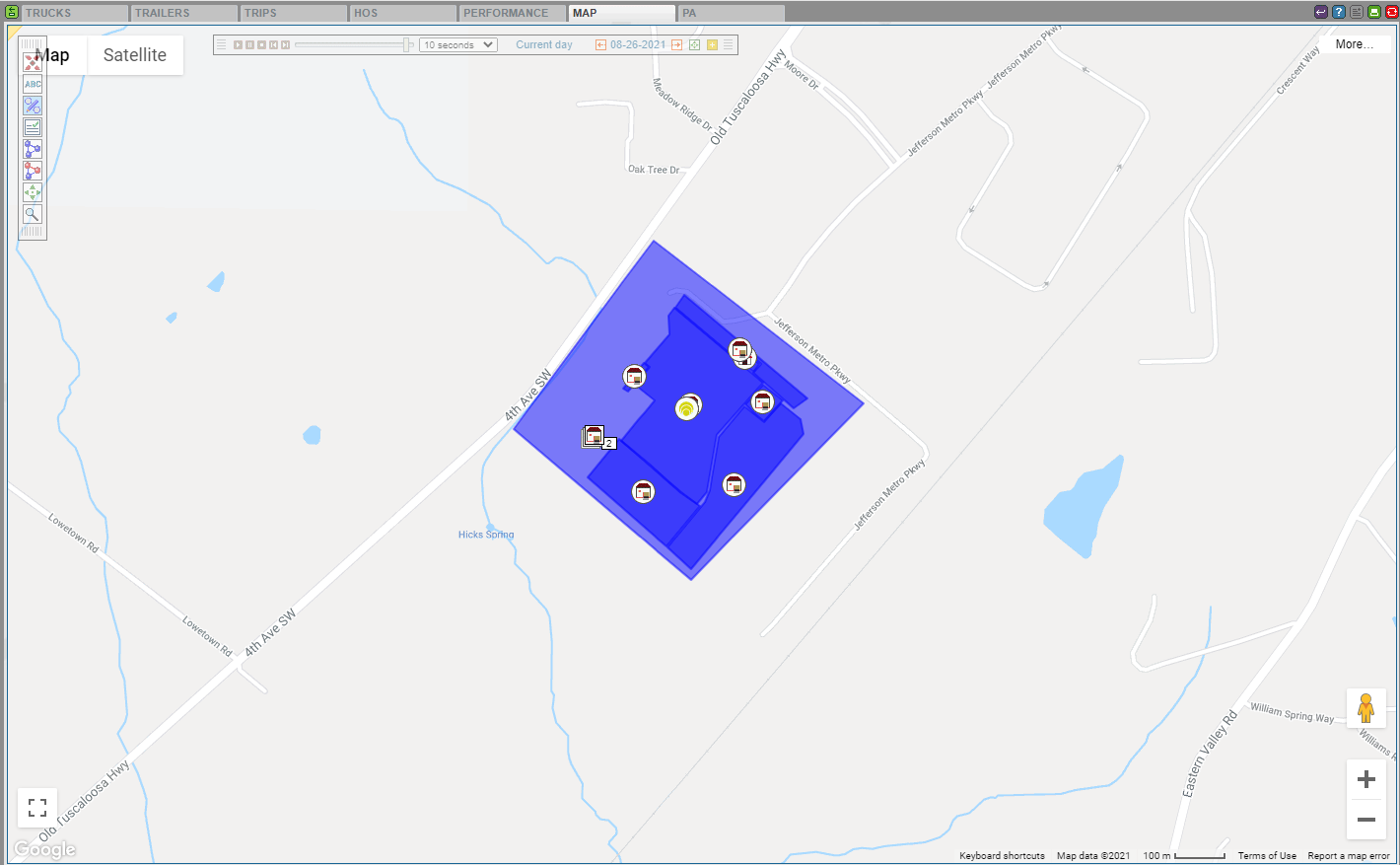

Telematics makes it easier for businesses to enforce safety standards. For example, access control solutions ensure that only trained operators can drive a forklift. Or, automated checklists can ensure that OSHA standards are met every time there’s a shift change.

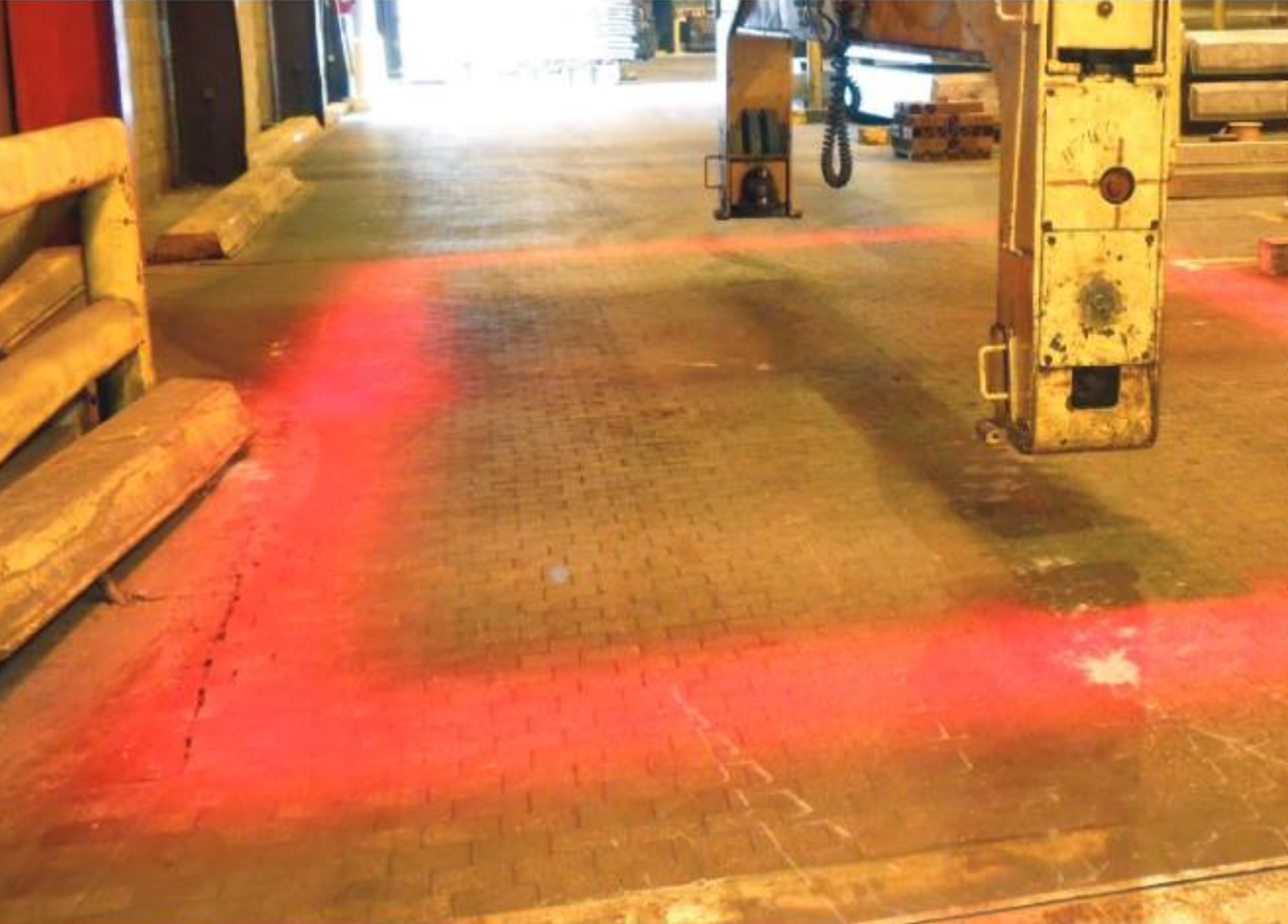

Other safety accessories can help employers maintain a safe working environment and defend themselves if an accident occurs. For example, lighting solutions can project a bright LED warning on the floor to designate active work areas and warn pedestrians.

Powerfleet’s Forewarner MAXI alerts pedestrians of elevated loads. Source: Powerfleet

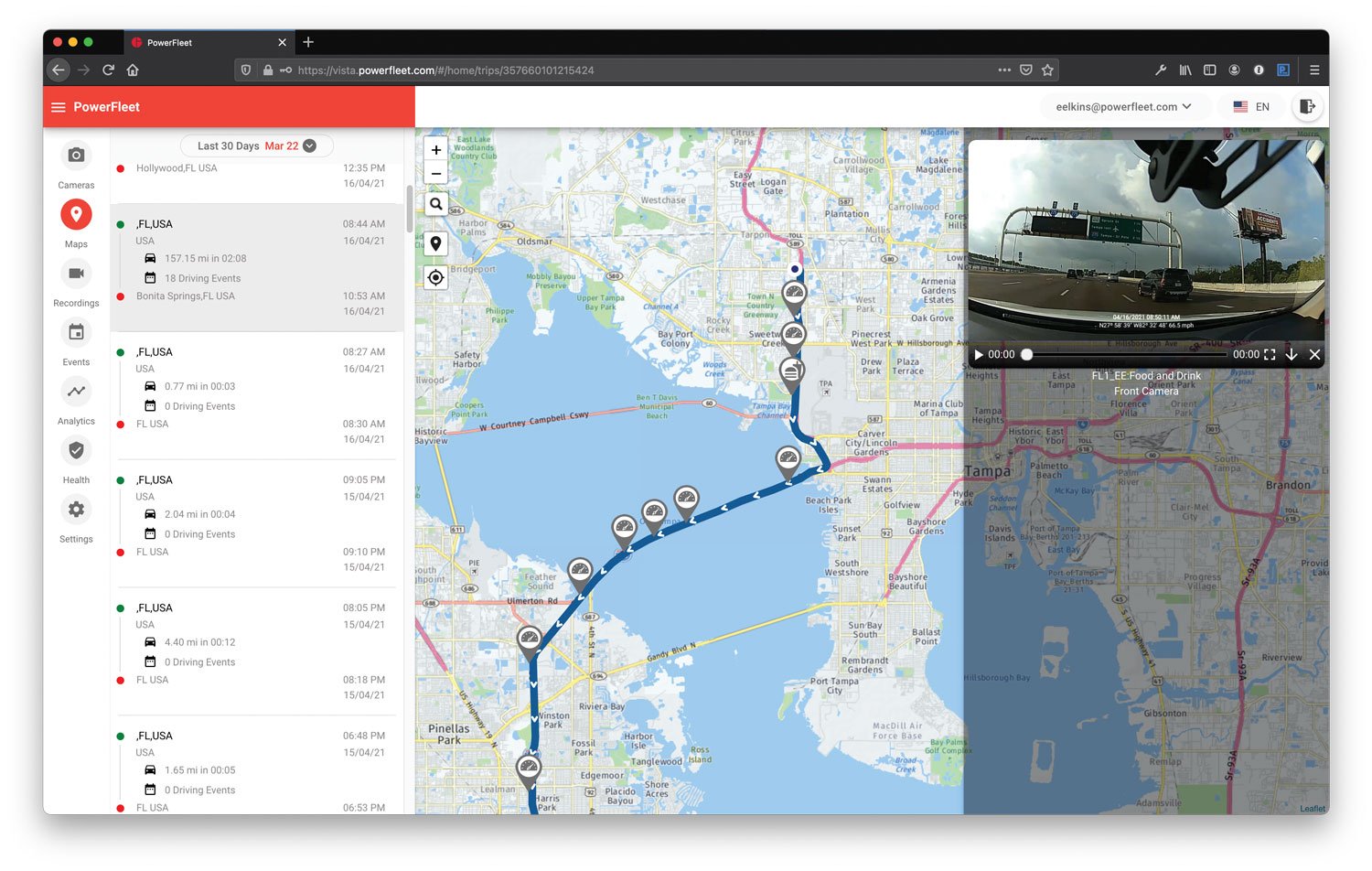

If an incident does occur, technology can provide critical evidence and documentation. For example, access control, speed monitoring, and impact management solutions paint a clear picture of each incident. The addition of camera systems provides an added visibility level while providing proof for insurance claims or legal processes.

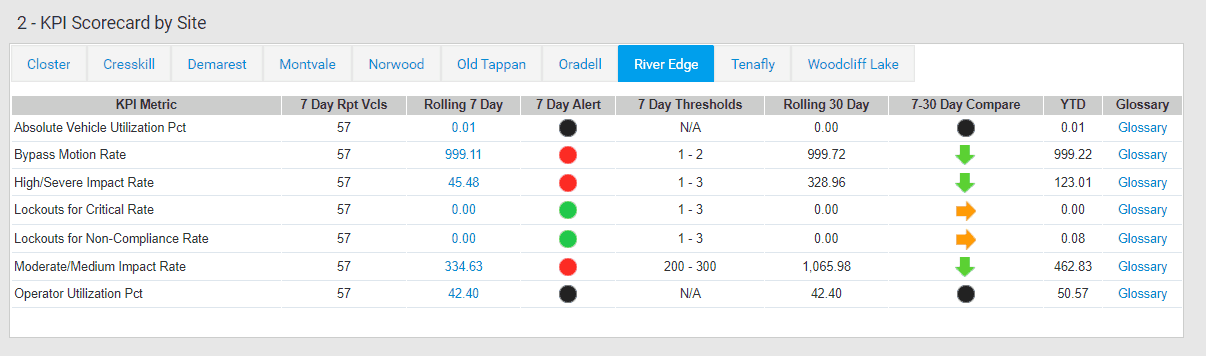

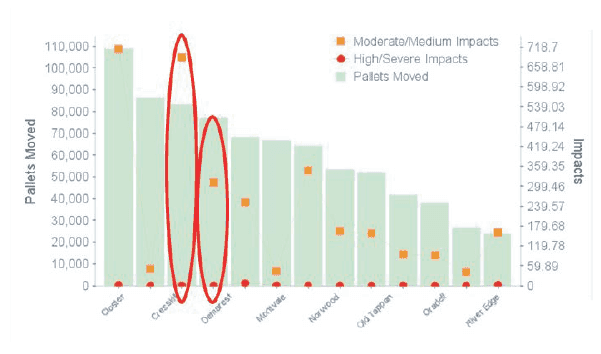

In addition to improving safety, telematics can help streamline operations and improve productivity and assessment of seasonal workers. For example, enterprise software solution, Powerfleet IQ, makes it easy to analyze forklift utilization levels across different locations and adjust allocations as needed by downsizing, purchasing new equipment, or transferring equipment. Powerfleet IQ also helps to monitor how individual operator driving habits identify individual or behaviors that pose a greater safety risk within the operation.

Powerfleet Leads the Way

Powerfleet provides a best-in-class solution for verifying compliance, tracking trends, and avoiding liability.

Powerfleet IQ integrates with a WMS and ERP system to provide a comprehensive and actionable overview of warehouse operations. With actionable intelligence in hand, you can reduce forklift-related damage costs by 60% to 90% while empowering managers to see who’s driving safely and who needs more training to be safe on the job.

You can also access essential KPIs, such as:

- Impact events per vehicle motion time.

- Rate of vehicle lockouts due to critical safety issues.

- Rate of vehicle lockouts due to failed pre-shift safety checklists.

Powerfleet also provides a range of other safety solutions for forklifts, including LED safety lights, speed and abuse monitoring, weighing systems, camera systems, and pedestrian alerts. These technologies ensure that operators, pedestrians, equipment, and facilities remain safe, particularly when seasonal employees are added to the mix.

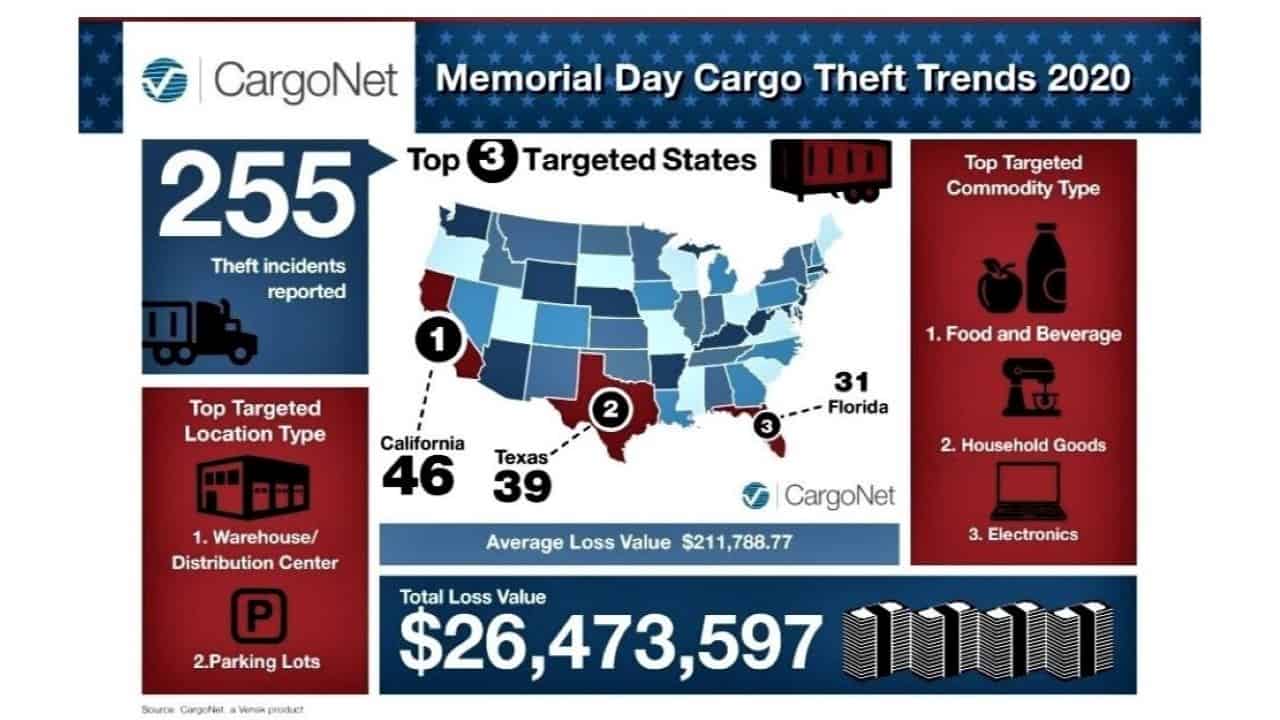

Finally, Powerfleet provides solutions beyond the warehouse, adding visibility to everything from freight to last-mile deliveries. For instance, our fleet telematics make it easy to track cargo across the supply chain and ensure on-time deliveries. Meanwhile, our vehicle telematics help managers optimize everything from fuel economy to asset allocations.

The Bottom Line

Many companies are starting to scale up their seasonal workforce to meet holiday demand and cover labor shortages. While hiring is of paramount importance, businesses shouldn’t neglect safety and training protocols as they struggle to meet demand. Fortunately, telematics can help ease these burdens and ensure that everything is running smoothly.

Beyond seasonal workers, Prologis estimates that transportation, warehousing, and related fields will add close to 735,000 jobs by 2031 to meet rising demand from e-commerce and other megatrends. Telematics help ensure that your business is ready to take on these growth rates without decreased productivity or an increase in safety concerns.

If you’re looking to add telematics to your fleet, contact us for a free consultation to discover how we can help deliver a compelling long-term return on investment with a short payback period.