Improve Safety with Pedestrian Warning Systems

Manufacturing and warehousing have the second-largest rate of preventable fatal work injuries of any sector—ahead of mining and construction.. In fact, approximately 11% of forklifts in the U.S. will be involved in an accident each year. In 2022 forklifts were responsible for 78 work-related deaths and 7,290 non-fatal injuries that affected days away from work. A serious injury usually involves worker hospitalization, days away from work and in some cases permanent disability, while a single forklift accident can cost $180,000 or more. So, if your facility has ten or more forklifts, there’s a good chance that you will experience at least one accident per year.

Fortunately, new technologies are improving workplace safety. For example, cameras provide forklift operators with increased visibility, LEDs alert pedestrians of a forklift’s presence in noisy work environments, and sensors aggregate safety data and enable managers to address problems before they result in injuries or fatalities.

Let’s take a look at breakthroughs in pedestrian warning systems and why you may want to consider them for your forklift fleets.

Forklifts are responsible for more than 96,000 non-fatal injuries each year, but fortunately, safety technologies are quickly improving—including new pedestrian warning systems. Click To TweetForklift Safety Challenges

Material handling equipment like forklifts frequently run products or materials throughout environments such as factories, plants and warehouses where pedestrians are present. The combination of fast-moving vehicles, blind corners, and a noisy environment create inherent risks that lead to fatal and non-fatal accidents.

Some common challenges include:

- Operators cannot simultaneously look at what they’re doing and be completely aware of their surroundings.

- Vertical stacking is necessary to maximize efficiency but creates the risk of dangerous falling objects.

- Loud work environments and hearing protection reduce the effectiveness of audible warnings like horns.

While some of these problems remain unavoidable, new technologies eliminate others, opening the door to safer work environments. Facility and equipment managers may want to consider adopting these technologies to prevent costly safety incidents. As a bonus, many of these technologies simultaneously provide actionable business intelligence.

AI-based Camera Solutions

Artificial intelligence, or AI, has made tremendous strides over the past several years. In particular, AI has become quite adept at recognizing objects, enabling machines to distinguish between pedestrians, other vehicles, signs and objects. These same technologies could also solve key forklift safety challenges.

While forklift cameras provide some level of visibility, operators cannot be watching camera feeds at all times—they also need to collect loads and transport them to their destination. AI-powered cameras provide an extra set of eyes by automatically recognizing the human form in any camera and triggering real-time alerts.

These systems improve upon traditional pedestrian monitors, which require tags that must be worn at all times by anyone walking around in a warehouse. AI-powered cameras don’t require any special equipment or procedural changes. You can mount multiple cameras to provide extra safeguards when it comes to pedestrian safety hazards.

The Pedestrian & Vehicle Warning System automatically detects pedestrians and ensures safety regardless of the PPE they’re wearing. Source: Powerfleet

Powerfleet’s Pedestrian and Vehicle Warning System doesn’t require the use of any tags or high-visibility vests to detect pedestrians, ensuring safety regardless of PPE standards. When combined with industrial telematics data, it can provide additional insights for identifying areas for improvement and driver coaching to help you promote a culture of safety at your facility.

Pedestrian & Vehicle Warning Systems

Powerfleet’s Pedestrian and Vehicle Warning System uses AI and up to three cameras to help prevent accidents and protect pedestrians, goods, and facilities. With two fully-configurable, 120-degree, field-of-view zones for each camera, you can provide operators with visual and audio advanced warning and critical action based on a hazard’s proximity.

Unlike many competing solutions, the Pedestrian and Vehicle Warning System doesn’t require pedestrians to wear special apparel or wearable tags and the system activates based on the direction of travel to avoid false positives. When capturing images of a dangerous event, the system also blurs out faces to ensure privacy while capturing data to help managers assess the situation.

Additional Pedestrian Safety Technologies

Non-camera based safety accessories such as Powerfleet’s Forewarner systems are also helpful in alerting pedestrians of nearby forklifts. Rather than relying on horns in noisy environments, Forewarner systems project a bright spot on the floor’s surface. With about 15 feet of warning time, pedestrians have a visible warning to get out of the way.

Other forewarning systems project solid blue or red LED lines below overhead crane hook locations. That way, pedestrians are immediately aware of any overhead risks that they may not be paying attention to when walking past. And like the other forewarners, these projections don’t rely on hearing in a noisy environment.

Powerfleet provides a range of visual forewarning systems, including its Forewarner Sideliner LED, and Forewarner MAXI for overhead objects. As with the Pedestrian and Vehicle Warning System, these technologies work with other telematics to improve overall safety and performance, creating a robust safety culture.

Cameras & Telematics

Many forklift safety hazards arise from risky driving habits. For example, overconfident drivers may speed back and forth when moving materials. Telematics provide an easy way to monitor these driving habits and address any problems before they result in injuries or fatalities. And when paired with cameras, you can use incident recordings for evidence or training footage.

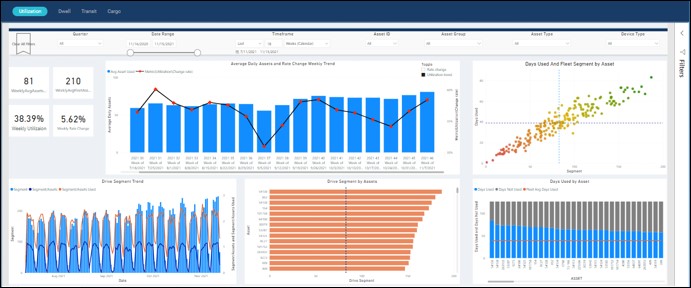

Powerfleet’s advanced telematics platform provides wireless, automated control, and monitoring of industrial vehicles. Managers can receive alerts in real-time through a cloud-based portal for analytics, coaching, and other purposes.

The combination of AI-powered cameras and telematics can help make your drivers safer and more productive with fewer accidents. In addition, you can ensure compliance with OSHA regulations and other workplace guidelines while minimizing liability.

The Bottom Line

Pedestrian safety is essential in manufacturing, warehouse, and other environments where material handling equipment is in use. While the combination of fast-moving vehicles, blind corners, and a noisy environment can create many hazards, new technologies proactively alert both operators and pedestrians when risky situations arise. The result is fewer safety incidents and a more streamlined work environment.

If you’re interested in transforming your fleet safety, contact us today, to schedule a free consultation.