The trucking industry operates with razor-thin profit margins, and fuel is the second-largest expense behind labor for fleet operators. While fuel prices are beyond the control of trucking companies, there are several ways to improve fuel efficiency through better driving habits, proactive maintenance, efficient route planning, and more.

Let’s look at some of these practices and how telematics can help implement them to maximize fuel efficiency across your fleet.

Fuel is the second-largest expense for trucking companies beyond labor—are you taking the proper steps to improve fuel efficiency? Share on XImproving Driver Habits

Drivers are the biggest expense for trucking companies, and they heavily influence the second largest cost—fuel.

According to data from the EPA, fleets could save thousands of dollars per truck each year by limiting excessive idling and reducing maximum speed limits. When multiplied across an entire fleet, these cost savings could amount to tens of thousands of dollars per year or more—even for a modest-sized fleet.

The most common way to improve driver habits is through proper training and education. In fact, two trucking fleets in Canada documented the impact of driver training and found 18% and 20% improvements in fuel efficiency, respectively. It’s one of the easiest ways to get started.

Of course, positive reinforcement helps improve compliance over the long term. Telematics solutions measure driver behavior in real-time, including speed, braking, acceleration, and other habits, making it easy for managers to reward good behaviors and address any problems early on.

Powerfleet’s LV-9000 makes it easy to track speeding, harsh braking, idling time, over-revving, and other driving behaviors.

Predictive Maintenance

Anyone that owns a car knows the importance of proactive maintenance to improve fuel economy and avoid breakdowns.

Regular and proactive maintenance is essential to improve fuel economy, satisfy federal regulations, extend vehicle lifespans, reduce the odds of emergency repairs, and increase fleet uptime. After all, a single roadside breakdown can cost thousands of dollars in lost productivity.

There are several critical parts to maintain:

- Lubricants reduce friction and wear-and-tear on the engine, transmission, and drivetrain. Using synthetic lubricants can improve fuel economy by at least 3%, saving nearly 500 gallons of fuel each year while reducing wear and maintenance.

- Underinflated tires produce heat and rolling resistance, reducing fuel economy by 0.5% to 1% per 10 psi below recommendations. According to a recent survey, less than half of tires were within 5% of the recommended inflation pressure.

- Old components often weigh much more than newer lightweight components, reducing fuel economy. Replacing these components with aluminum, metal alloys, metal matrix composites, and other lightweight components can improve your mileage.

Tracking all these maintenance items can be a nightmare when you multiply them by an entire fleet of trucks. Moreover, mileage-based maintenance may not be the best way to plan maintenance since it doesn’t necessarily correlate with actual maintenance problems.

Predictive maintenance involves using telematics to track vehicle usage patterns and predict optimal maintenance times. For example, different drivers may have separate braking habits that influence brake pad and engine health, creating unique maintenance requirements.

More Efficient Logistics

Inefficient logistics operations can lead to trucks traveling empty, unnecessarily idling, and using longer or congested routes.

By some estimates, 15% or more of annual truck miles may be empty miles that don’t generate any revenue. Typical long-haul trucks could be driving 15,000 miles per year and consuming over 2,400 gallons of diesel fuel without cargo in these instances.

Idling consumes about 0.8 gallons of fuel per hour. While idle time is often necessary (e.g., when outside temperatures are low), there may be an opportunity to significantly cut down on fuel usage if you can reduce unnecessary idling time.

The combination of telematics and intelligent routing software can help improve logistics:

- Intelligent routing software optimizes routes based on driver hours of service, vehicle size constraints, equipment availability, and other factors to maximize fuel economy.

- Telematics can help track detention times and enforce shipper or receiver fines. You can also identify internal materials handling teams that may be causing unnecessary detention times.

- Telematics can show the real-time locations of fleet assets to proactively alert receiving docks before a truck arrives, enable live-loads, and avoid empty trailers.

The EPA estimates that a mere 1% reduction in empty miles could save over 100 gallons of fuel and increase ton-miles by nearly 20,000 per year. At the same time, reducing idling time by 5% could save another 100 gallons of fuel each year, resulting in a far superior fuel economy.

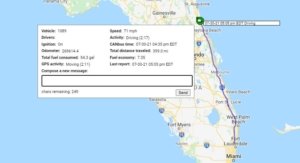

Powerfleet’s LV9000 ELD data in its user application – Source: Powerfleet

Powerfleet’s Vista Dashboard – Source: Powerfleet

Powerfleet’s cutting-edge software makes it easy to realize these benefits. For example, fleet managers can instantly see all their fleet assets on an interactive map and configure alerts for excess idle time.

Identifying EV Possibilities

Trucks waste a lot of energy during deceleration and braking, especially when they frequently stop or slow down.

Hybrid engines recapture energy from deceleration and braking and store it in a secondary power source that provides extra power when climbing a hill or accelerating to pass a vehicle. As a result, short-haul trucks can improve fuel economy by 30% to 50% using hybrid engines.

Electric vehicles will play an essential role in the future of trucking. While the electrification of long-haul fleets might be a long-term goal, there may be opportunities to electrify or hybridize short-haul or medium-weight vehicles as part of your normal replacement cycle.

In addition to electric vehicles, many large automakers are developing hydrogen fuel cell-powered semi-trucks. These trucks will be quiet, smooth, and powerful without emitting anything other than water. Fuel cells could also have a range of about 300 miles with fast refueling.

The Bottom Line

Fuel is the second-largest expense after labor for trucking companies. While fuel prices aren’t controllable, there are many ways to improve fuel economy through better driving habits, proactive maintenance, and better logistics. Trucking companies may also want to consider hybrids or EVs.

The best way to improve fuel economy is through the use of telematics. Powerfleet provides a wide range of telematics solutions designed to track everything from driver behaviors to fuel economy and maintenance needs. Fleet managers can track these data points in an easy-to-use dashboard.

Browse our product catalog or contact us to schedule a free consultation to start reducing your fuel costs today!