Material handling is both a leading source of safety incidents and a vital part of warehouse operations. As a result, these operations are an ideal target for telematics solutions that can effectively reduce safety incidents and improve productivity. The key is tracking the right metrics and aligning stakeholders behind a common goal.

Let’s take a look at how analytics can help improve material handling safety, as well as some tips to implement these practices in your warehouses.

Material handling is both a leading source of safety incidents and a vital part of warehouse operations—here's how telematics can improve both areas. Share on XSafety is a Top Concern

OSHA estimates that forklifts account for 61,800 minor injuries, 34,900 serious injuries, and 85 forklift-related deaths each year. With about 900,000 forklifts in the U.S., those numbers amount to a 1-in-10 chance that each forklift will be involved in an accident this year. Meanwhile, one out of every six workplace deaths is forklift-related.

Forklift fatalities occur for many reasons:

| Accident Type | Percentage (%) |

| Crushed by vehicle tipping over | 42% |

| Crushed between vehicle and surface | 25% |

| Crushed between two vehicles | 11% |

| Struck or ran over by a forklift | 10% |

| Struck by falling material | 8% |

| Fall from the platform on forks | 4% |

OSHA believes that standardized training and safety procedures could prevent 70% of forklift accidents. After all, the most common causes of safety incidents are preventable things like speeding, cornering, giving rides, or a lack of warning signs or floor markings. The key is correcting these poor behaviors before they cause an incident.

According to the National Safety Council, the average direct worker injury cost to a company is $38,000, with $150,000 in additional indirect costs. OSHA can also fine companies up to $7,000 for minor infractions and up to $70,000 for repeat offenders. Given the high financial and human costs of injuries, preventive technologies are always worth the investment.

Productivity Drives Value

Materials handling is a critical part of any warehouse operation. By some accounts, they comprise 10% to 80% of the product cost, with the percentage rising for inexpensive or commodity products. Materials handling functions also consume more than 90% of the product flow time within manufacturing businesses.

There are two key ways to measure materials handling productivity:

- Labor Productivity: The time forklift operators spend actively working. If operators are waiting around too much, there may be an opportunity to optimize labor costs.

- Materials Productivity: The number of pallets moved by lift truck operators. Comparing pallets per hour across operators or facilities can help benchmark and improve productivity.

- Asset Productivity: How often is high valued equipment sitting idle. Knowing peak demands and concurrent usage is key to optimizing fleet requirements.

There are also many different strategies to improve productivity:

- Optimize facility layout. Slotting popular items near each other and closer to packing/staging areas, identifying and addressing areas of congestion, and adding traffic control devices can help dramatically improve productivity for all operators.

- Implement proper training. Consider assigning new forklift operators an experienced mentor to help answer questions beyond the introductory PowerPoint training sessions. Cross-training employees can also help improve their productivity.

- Maintain your equipment. Ensure that equipment is well-maintained to avoid costly breakdowns while investing in side shifters, fork positioners, or other capabilities that can help increase flexibility and productivity within fork trucks.

Unfortunately, many of these improvements require a blind investment. For example, investing in new equipment should theoretically improve productivity, but it’s hard to prove the return on investment without tracking productivity at a granular level. Data is critical to understanding the impact of these investments and encouraging more investments.

Telematics Optimizes Safety & Productivity

Telematics improve safety and productivity through actionable data. For example, telematics solutions can help lock out untrained operators, enforce electronic OSHA checklists, and sense impacts to foster a safety culture. The same technologies can measure the amount of time a fork truck operator is active and how many pallets they’re moving per hour.

Powerfleet is a leading provider of telematics solutions. We recently helped a long-term customer in the food and beverage industry adopt our technologies on more than 2,500 pieces of materials handling equipment across nearly 100 food and beverage manufacturing and distribution facilities, providing a pivotal case study in the potential benefits.

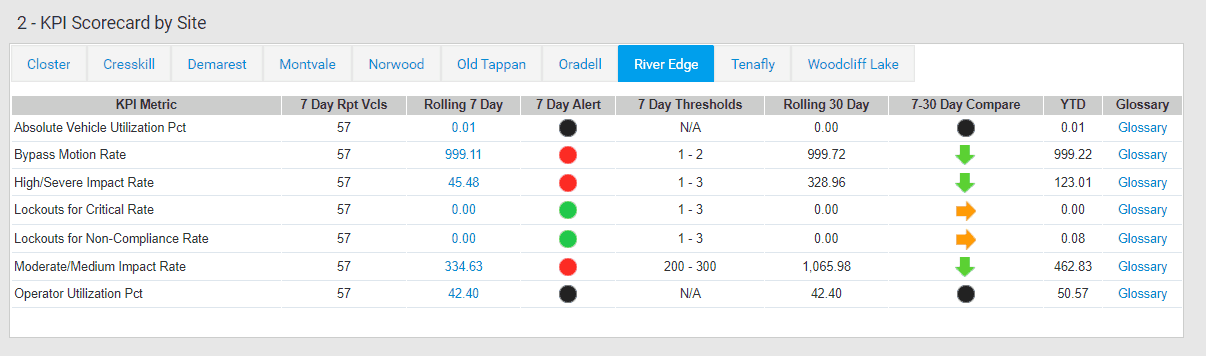

Powerfleet’s KPI Scorecards – Source: Powerfleet

The customer opted to track three key performance indicators:

- Time forklift operators spent actively working

- Number of pallets moved by lift truck operators

- Number of damage-causing impacts recorded by total pallets moved per lift truck operators

The customer then developed a plan to encourage every stakeholder—including managers, operators, supervisors, and executives—to invest in the outcome. After all, investing in technology without a clear plan of action leads to an expensive set of useless data. The key to success is defining the data that matters and effectively using it.

The “carrot-and-stick” plan included:

- Develop a consistent set of measurements for material handling productivity and safety, regardless of the size of the facility.

- Establish new benchmarks for pallet moves versus lift truck motion time and impact events.

- Set up key performance indicator (KPI) scorecards for drivers, supervisors, and warehouse managers.

- Award cash bonuses and other incentives for meeting KPI targets.

- Retrain or repurpose forklift operators who fail to meet the benchmarks for safe productivity.

Powerfleet’s SAP Integration – Source: Powerfleet

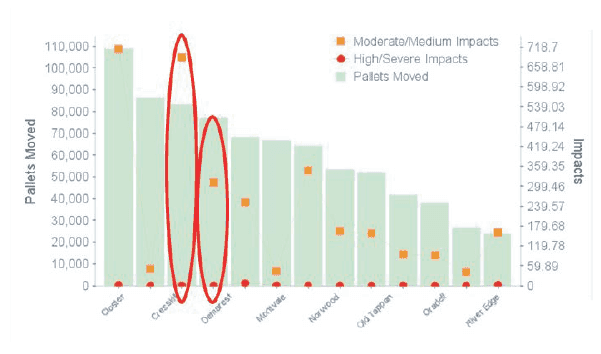

We worked with the customer to integrate Powerfleet IQ with its Kronos time-card system and SAP warehouse management system to chart data points like paid time versus seat time, time in motion with load, and lift truck impacts versus the number of pallets moved. We also worked together to build easy-to-use KPI scorecards for relevant parties.

In the end, the implementation resulted in an 85% reduction in accidents and damage, 100% compliance with crucial safety metrics, and a better way to measure safety and productivity across the organization.

The Bottom Line

Materials handling is a common source of safety incidents and a vital part of warehouse operations, making it a natural target for telematics solutions. By tracking the correct data, integrating existing systems, and aligning stakeholders, you can develop actionable metrics and KPI scorecards that drive a tangible return on investment.

Powerfleet IQ Analytics is a robust analytics platform that translates data from vehicles, operators, and other sources into actionable KPIs. You can easily compare operational performance across sites, drill down to specific vehicles, or see high-level profiles. You can use the data to improve safety, streamline maintenance, and optimize productivity.

Contact us for a free consultation and learn how to improve your materials handling operations with telematics solutions!