Corporate Hq

123 Tice Blvd. Suite 101

Woodcliff Lake, NJ 07677

Follow Us

©2025 Powerfleet. All Rights Reserved

Origin Energy operates a diverse fleet that spans urban environments and remote areas of Australia. Powerfleet delivered a comprehensive asset management solution.

Unitrans operates over 1,500 vehicles in Southern and Eastern Africa, ranging from agricultural tractors to land trains.

This Australian company is a global leader in mobile and fixed plant equipment maintenance, with a focus on the mining and civil construction sectors.

Streamline Productions, renowned for orchestrating live events across North America, was built on the principle of efficiency.

Operating for over a decade, Redden Concrete has continually expanded its fleet and needed reliable fleet management solutions.

NPL Canada is a key player in natural gas infrastructure services and part of Centuri Group, Inc. Operating across 13 regional hubs in Ontario, NPL Canada.

[help]

Origin Energy operates a diverse fleet that spans urban environments and remote areas of Australia. Powerfleet delivered a comprehensive asset management solution.

[help]

The Sizzle Video introduces Powerfleet and the Unity platform, showing how our technology unifies data across vehicles, equipment, and facilities to deliver complete operational visibility.

[help]

The On-Site Demo demonstrates how Powerfleet’s Unity platform supports safer, more efficient industrial operations through automation and data intelligence. The video follows a real scenario where automated safety checklists, AI-powered alerts, and integrated maintenance tools prevent downtime and improve performance.

[help]

The Unity Demo highlights how Powerfleet’s Unity platform collects, standardizes, and connects data from any system, device, or provider to create a single operational view.

[help]

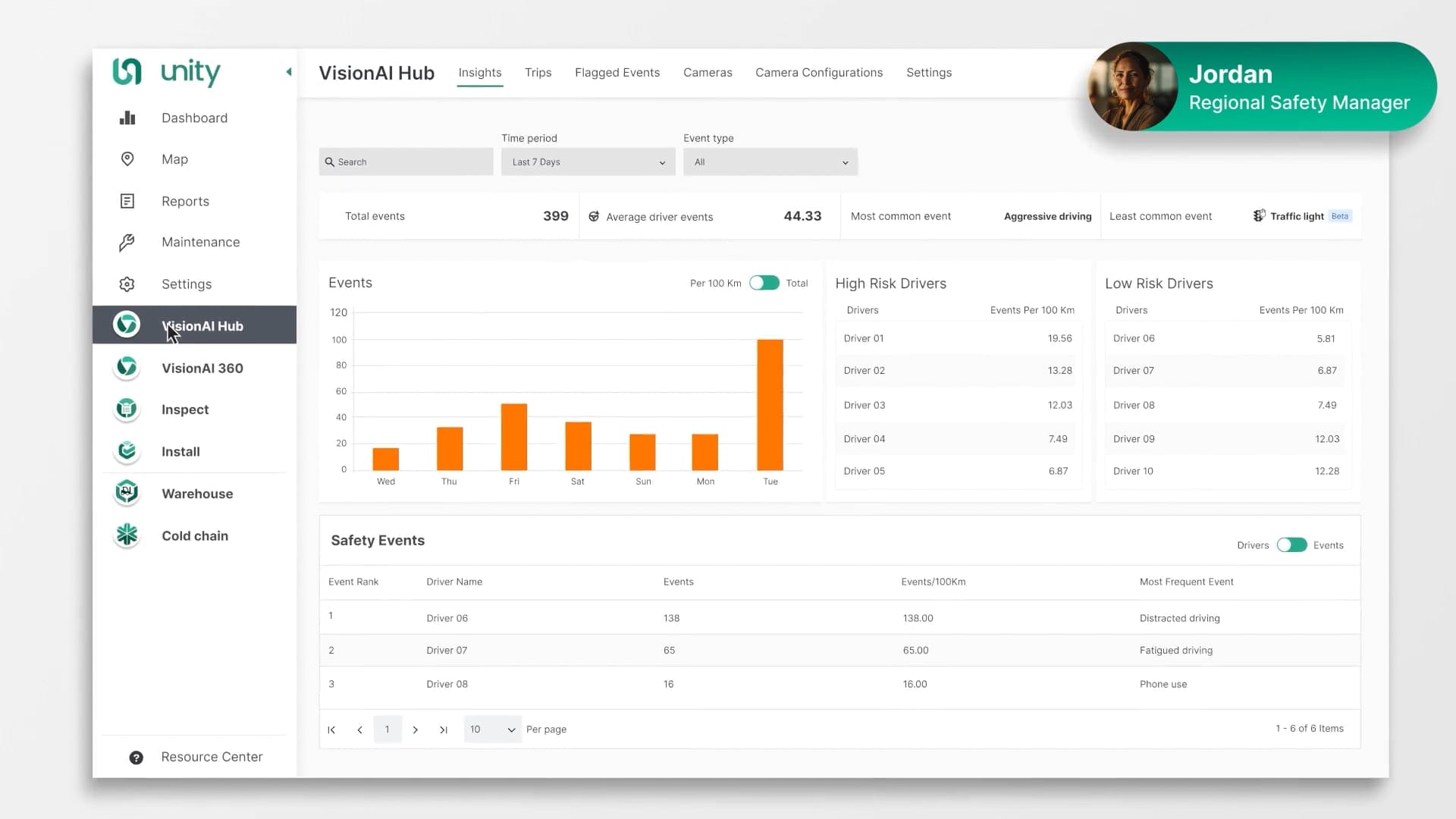

The VisionAI Demo presents VisionAI Hub, an AI-powered video solution within Powerfleet’s Unity platform that improves driver safety and performance in real time.

[help]

Unitrans operates over 1,500 vehicles in Southern and Eastern Africa, ranging from agricultural tractors to land trains.

[help]

This Australian company is a global leader in mobile and fixed plant equipment maintenance, with a focus on the mining and civil construction sectors.

[help]

Streamline Productions, renowned for orchestrating live events across North America, was built on the principle of efficiency.

[help]

Operating for over a decade, Redden Concrete has continually expanded its fleet and needed reliable fleet management solutions.

[help]

NPL Canada is a key player in natural gas infrastructure services and part of Centuri Group, Inc. Operating across 13 regional hubs in Ontario, NPL Canada.