Lift Truck Telematics & Distribution Operations

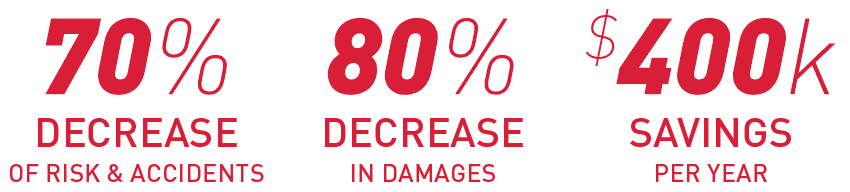

Powerfleet® removed risk factors and applied enforceable safety measures for a large food manufacturing company. Each location received technologically advanced and easily implemented processes for worker safety and vehicle tracking. Powerfleet®’s advanced telematics digitise tracking, enabling management at any location to monitor vehicle use and employee habits. This eliminated guesswork, provided accountability and created a new system of checks and balances for measurable results. The company saw results in terms of a 70% decrease in accidents, an 80% decrease in damages and several hundred thousand dollars in cost savings.

Situation

Powerfleet®’s advanced telematics digitise tracking, enabling management at any location to monitor vehicle use and employee habits. This eliminated guesswork, provided accountability and created a new system of checks and balances for measurable results.

The company saw results in terms of a 70% decrease in accidents, an 80% decrease in damages and several hundred thousand dollars in cost savings.

Task

Improvements were required in the following areas:

- Control over 3PL operations, specifically equipment use, personnel training, and accountability.

- Reduction of industrial truck accidents and vehicle damage, which was costing the company nearly half a million dollars each year.

The company has a fleet of over 150 industrial trucks, which include motorised walkie-rider pallet jacks, reach trucks and sit-down counterbalance forklifts. They required immediate help with monitoring personnel and reducing safety threats.

Action

Powerfleet® is an expert in streamlining safety operations. The intelligent designs and systems improvement transformed this company’s operations, drastically reducing risk and improving safety. The company needed a wireless telematics system designed for industrial trucks. Powerfleet® put into place:

- Access control system: this ensures that only trained operators are using certain types of equipment and vehicles in need of repair are locked.

- Electronic safety lists that comply with OSHA regulations and can identify mechanical issues before they become critical or dangerous.

- Collision detection and accident management, which logs the identity of the driver when impact occurs.

Based on pricing, reliability and overall value, this company selected Powerfleet® as the best option on the market to implement these systems.

Powerfleet®’s services provide OEM-independent solutions over a long period of time. They implemented the above systems, many of which are patented and unique to Powerfleet® as a company.

Powerfleet’s® implementation of software and hardware happened over the course of just a few weeks.

Powerfleet Took These Steps

- Vehicle-mounted devices that include on-screen Wizard

- Integrated with existing systems

- Validated system’s interface with every brand of truck

- Ensured accurate and consistent data flow

- Installed badge-reading technology for existing employee ID cards

- Vehicle access control

- Installing a patented electronic safety checklist system

Results

The client reports that Powerfleet® achieved the following results:

- Real-time data for deep fleet utilisation

- Authentic monitoring of how operators are using equipment

- Improved processes and efficiency

- Increased productivity of material handling operations

Additional outcomes eliminated badge-sharing among employees, created a “driver break” function to prevent unauthorised vehicle use and actioned an alert system for any maintenance issues or safety violations. The combined efforts had the additional results of:

- Eliminating cost, time and trouble of paper-based records and communication

- Early identification of equipment repair needs

- Reduction in unsafe operation procedures and expensive repairs

- A higher rate of vehicle mobilisation and safe use (due to timely repairs)

Conclusion

Powerfleet®’s patented, industrial management technology transforms drivers’ situational awareness and reduces the number of accidents. It streamlines real-time communication and eliminates false alarms. Managers can respond quickly to accidents or safety events and create proactive measures to avoid costly issues. With integrated systems, meaningful data can be collected that informs best practice and better processes for the companies who use Powerfleet®’s software and hardware.

Europe

Europe  North America

North America  Germany

Germany  Asia-Pacific

Asia-Pacific  Africa

Africa  Argentina

Argentina  Mexico

Mexico